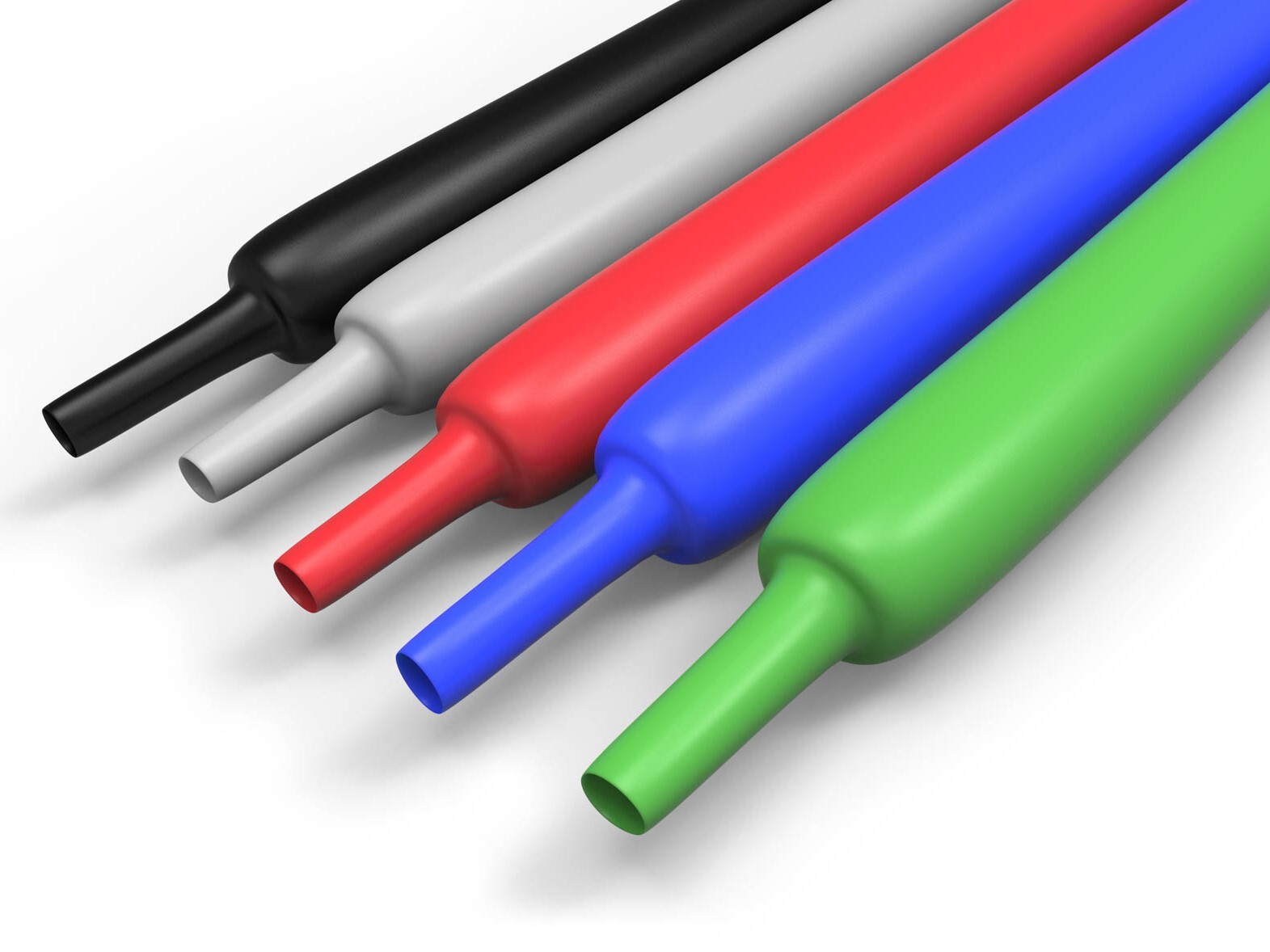

We offer a great variety of sizes (3/32” to 1”) and colors (black, red, white, blue, clear). Wirefy assorted heat shrink tubing comes organized in preconfigured kits to keep things neat and tidy. This industrial grade heat shrinkable tubing is UL listed and is compliant with all relevant electrical standards such as: SGS, RoHS, Reach, and ISO9001.

This wire heat shrink tubing is flame retardant. Dual wall tubing design has the increased ability to stand up to wear and tear. Electrical Heat Shrink Tubing with Dual Wall Designĭual wall marine grade heat shrink tubing provides better rigidity and abrasion resistance. For best results we recommend using a heat gun. When adhesive flows, it pushes the air out and fills any gaps between the wire and the tubing, which makes the connection waterproof. Heat activated glue strongly adheres to wires, terminals or any other surfaces. A small fillet of clear adhesive (about 1 mm wide) becomes visible at the end of the heated tubing. When heat is applied, shrink tubing recovers and the internal adhesive layer melts. Where is Heat Shrink Tubing Used to provide electrical insulation (covering terminals, splices, wire repairs, or other connectors) to bundle loose items (. This is a waterproof shrink tubing with the internal adhesive layer. Additionally, 3:1 marine heat-shrink tubing shrinks around wires and terminals more tightly, eliminating any air gaps.īest Heat Shrink Tubing Comes with Adhesive Lining Therefore, 3:1 shrink ratio tubing can be used in significantly more applications compared to 2:1 shrink ratio tubing. Its high recovery ratio makes it possible to repair most damaged cable jackets without removing connectors. When heat is applied, this wire shrink wrap tubing will recover to a 1/3 of its original diameter.

#Heat shrink professional#

This tailored compression curve allows for additional ply compaction, elimination of air voids in the part walls, and produces a clean, resin-rich surface finish.ĭunstone's Hi-Shrink Tapes are tailored to suit applications with temperature requirements up to 165☌ with our polyester (mylar) films, up to 180☌ with our ETFE films, and up to 400☌ with our polyimide (Kapton) shrink tapes.Wire Heat Shrink Tubing: Professional Insulation and Cable ProtectionĪre you looking to fix a damaged wire, seal out moisture, or provide enhanced strain relief? Wirefy waterproof wire heat shrink tubing is an easy to use solution that can be used in automotive, marine, hobby RC, and home electrical wiring projects. Therefore, our Hi-shrink films will apply the optimum amount of compressive strength right when you need it, as your resin begins to flow. This factor is just one reason Hi-Shrink tape users use, on average, 50-75% less material than other compaction films.ĭunstone's heat-shrinkable tapes will begin to shrink at 70☌ and reach maximum shrink force in the 120☌ to 160☌ range. Unfortunately, this characteristic is less than optimal when your application demands quality lamination and a void-free cure. However, these films will relax as the temperature of the cure cycle increases, at the same time that the resin in the composite part begins to drop in viscosity and flow. They are wrapped, under high tension before the component enters the curing oven. Some non-shrinking films, such as cellophane, nylon, or polypropylene (OPP), are commonly used to overwrap composite parts to provide compression during cure. Available Dimensions: Rolls up to 20" wide x 1200 yards long.Release Coating: With or Without, Single Sided or Double Sided.Materials: Polyester (Mylar), ETFE, Polyimide (Kapton).Shrink tape is available in release coated(R) and non-release coated versions(S). Shrink tape is used as an alternative to vacuum bagging or autoclaving parts, though it can be used in conjunction with both methods. The compressive force generated by the shrinking of the tape is enough to consolidate or laminate multiple layers of material. When wrapped around a part, our heat shrink tape is designed to constrict and squeeze the underlying structure as heat is applied, typically during a curing process. WHAT IS HI-SHRINK TAPE? Heat shrinkable tape that applies compressive force to the underlying part.

0 kommentar(er)

0 kommentar(er)